Bolt and Screw Preload Free Calculator | Mechanic Calc Tool – Torque

Connections elements are fundamental components in each mechanical assembly, even in the Motorsport industry and at F1 level. The tool below provides an easy estimation tool of the axial preload on a bolt or screw given a data torque.

How to compute preload force on bolt and screw from torque.

In order to successfully use the preload mechanic tool you need the following data:

- Nominal diameter of the bolt or screw.

- Torque to be applied to the screw/bolt.

- Value of friction expected on the connection plate. If no data are available, leave the default value.

Preload force on bolts and screws explained.

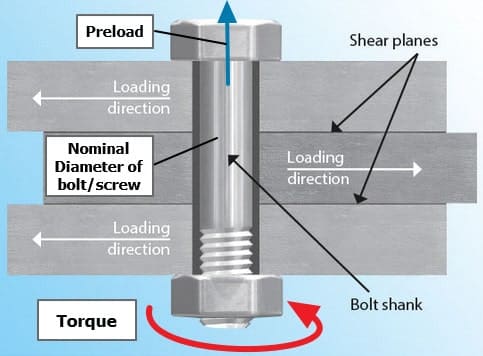

The torque applied to a bolt/screw is converted in a compressive force (clamp force) to keep the assembly components connected. In fact, the torque applied to the nut causes it to slide up the inclined plane of the threads. The relative motion between the nut and the bolt reduces the distance (called grip length) between the bearing surfaces of the bolt and nut. When the joint members within the grip resist, in the bolt a traction force, called preload force develops.

The relationship between preload and tightening torque can be derived from the principle of virtual work:

\(\begin{align}Torque=K\cdot P \cdot D\end{align}\)

where D is the nominal diameter of the fastener, P is the preload and K is the friction. K is about 0.2 for a black screw. For a lubricated fastener or one with cadmium plaiting, K is about 0.15 while unlubricated zinc-plated screws may have a K as high as 0.35. In general, preload is a function of a lot of variables, such as fastener material and finish, head style, and lubrication. However, the following mechanic tool serve as useful guide for bolt and threaded joint design and dimensioning.

Stress check on bolt and screw under preload and combined load.

Given the axial preload calculated above, it is possible to perform a stress check of your bolt/screw connection under external load. For the bolt/screw stress check tool to work, you only need the following:

- External loads (axial and shear loads)

- Yield strength of the material of the bolt/screw. You can find a datasheet of Yield Strength for the most common materials here.

- Nominal diameter of resistant minimum section of the bolt/screw

The tools work with both Metric/International Units and Imperial Units. If a safety factor < 1.5 is revealed, the joint connection may be unsafe. In case the output on the compressive force is negative, the joint connection is likely to open under the external axial load (in general because external axial load > preload force). For more information about the stress check and Von Mises Criterion, see our article here.