Dynamic properties of tyres: tyre uniformity

What are the dynamic properties of tyres?

Definition of tyre uniformity.

Tyre Uniformity refers to the dynamic mechanical properties of pneumatic tires as strictly defined by a set of measurement standards and test conditions accepted by global tire and car makers. These standards include the parameters of radial force variation, lateral force variation, conicity, plysteer, radial run-out, lateral run-out, and sidewall bulge. Tire makers worldwide employ tire uniformity measurement as a way to identify poorly performing tires so they are not sold to the marketplace. Both tire and vehicle manufacturers seek to improve tire uniformity in order to improve vehicle ride comfort. You are Matlab user and you want to discover how to manage large data for tyre modelling check this MathWorks link.

Stress and Forces on tyres.

The circumference of the tire can be modeled as a series of very small spring elements whose spring constants vary according to manufacturing conditions. These spring elements are compressed as they enter the road contact area, and recover as they exit the footprint. Variation in the spring constants in both radial and lateral directions cause variations in the compressive and restorative forces as the tire rotates. Given a perfect tire, running on a perfectly smooth roadway, the force exerted between the car and the tire will be constant. However, a normally manufactured tire running on a perfectly smooth roadway will exert a varying force into the vehicle that will repeat every rotation of the tire. This variation is the source of various ride disturbances. Both tire and car makers seek to reduce such disturbances in order to improve the dynamic performance of the vehicle.

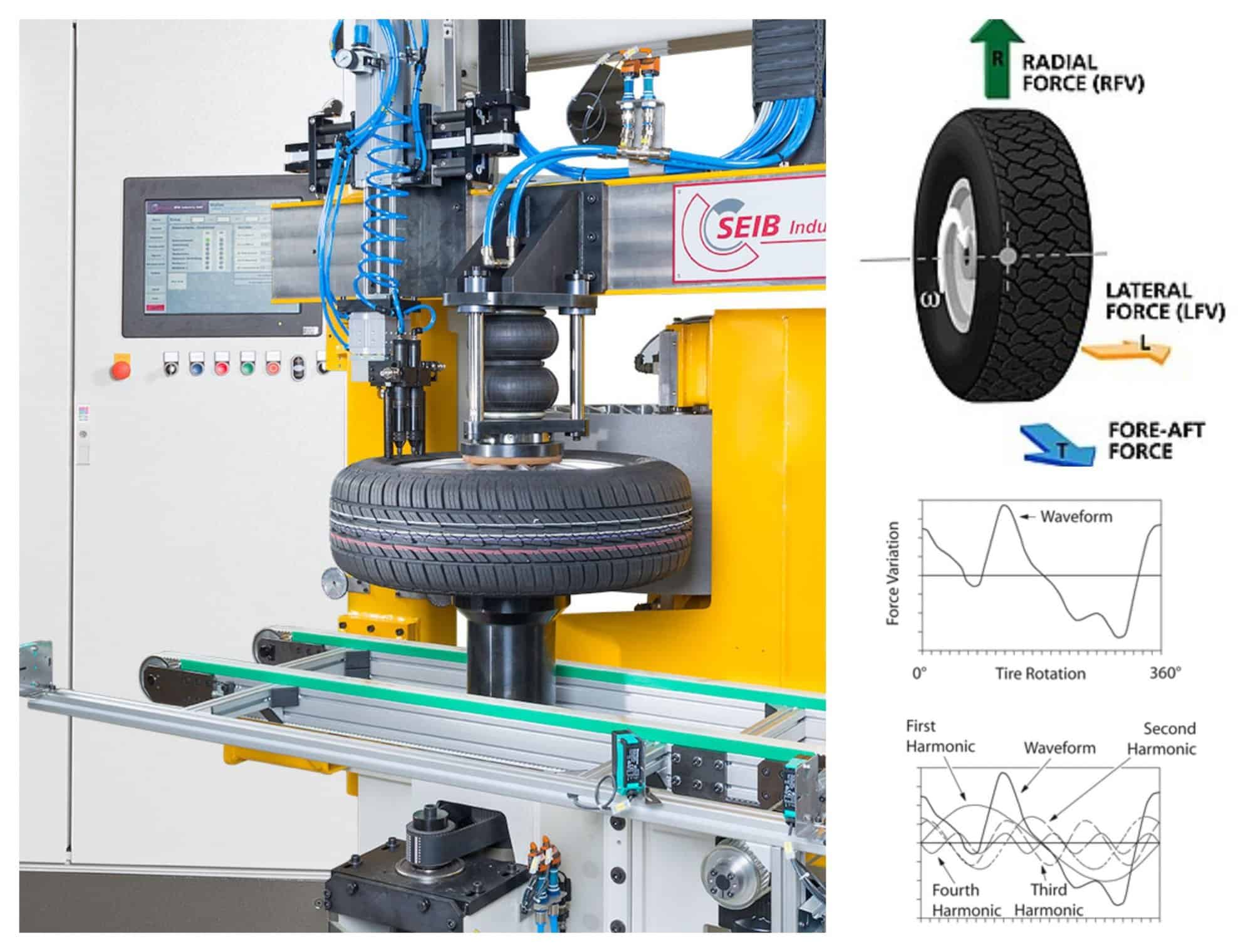

Tire forces are divided into three axes: radial, lateral, and tangential (or fore-aft). The radial axis runs from the tire center toward the tread, and is the vertical axis running from the roadway through the tire center toward the vehicle. This axis supports the vehicle’s weight. The lateral axis runs sideways across the tread. This axis is parallel to the tire mounting axle on the vehicle. The tangential axis is the one in the direction of the tire travel.

Which are the main parameters to assess the dynamic properties?

-

Radial Force Variation

In so far as the radial force is the one acting upward to support the vehicle, radial force variation describes the change in this force as the tire rotates under load. As the tire rotates and spring elements with different spring constants enter and exit the contact area, the force will change. Consider a tire supporting a 1,000 pound load running on a perfectly smooth roadway. It would be typical for the force to vary up and down from this value. A variation between 995 pounds and 1003 pounds would be characterized as an 8-pound radial force variation (RFV). RFV can be expressed as a peak-to-peak value, which is the maximum minus minimum value, or any harmonic value as described below.

Some tire manufactures mark the sidewall with a red dot to indicate the location of maximal radial force and runout, the high spot. A yellow dot indicates the point of least weight.

Radial run out of a tyre.

Radial run out (RRO) describes the deviation of the tire’s roundness from a perfect circle. RRO can be expressed as the peak-to-peak value as well as harmonic values. RRO imparts an excitation into the vehicle in a manner similar to radial force variation. RRO is most often measured near the tire’s centerline, although some tire makers have adopted measurement of RRO at three positions: left shoulder, center, and right shoulder.

Some tire manufactures mark the sidewall with a red dot to indicate the location of maximal radial force and runout.

-

Lateral Force Variation

Insofar as the lateral force is the one acting side-to-side along the tire axle, lateral force variation describes the change in this force as the tire rotates under load. As the tire rotates and spring elements with different spring constants enter and exit the contact area, the lateral force will change. As the tire rotates it may exert a lateral force on the order of 25 pounds, causing steering pull in one direction. It would be typical for the force to vary up and down from this value. A variation between 22 pounds and 26 pounds would be characterized as a 4-pound lateral force variation, or LFV. LFV can be expressed as a peak-to-peak value, which is the maximum minus minimum value, or any harmonic value as described above. Lateral force is signed, such that when mounted on the vehicle, the lateral force may be positive, making the vehicle pull to the left, or negative, pulling to the right.

Conicity of a tyre.

Conicity is a parameter based on lateral force behavior. It is the characteristic that describes the tire’s tendency to roll like a cone. This tendency affects the steering performance of the vehicle.

In order to determine Conicity, lateral force must be measured in both clockwise (LFCW) and counterclockwise direction (LFCCW). Conicity is calculated as one-half the difference of the values, keeping in mind that CW and CCW values have opposite signs. Conicity is an important parameter in production testing. In many high-performance cars, tires with equal conicity are mounted on left and right sides of the car in order that their conicity effects will cancel each other and generate a smoother ride performance, with little steering effect. This necessitates the tire maker measuring conicity and sorting tires into groups of like-values.

Ply steer definition for tyres.

Ply steer definition for tyres.

Ply steer describes the lateral force a tire generates due to asymmetries in its carcass as is rolls forward with zero slip angle and may be called pseudo side slip. It is the characteristic that is usually described as the tire’s tendency to “crab walk”, or move sideways while maintaining a straight-line orientation. This tendency affects the steering performance of the vehicle. In order to determine ply steer, the lateral force generated is measured as the tire rolls both forward and back, and ply steer is then calculated as one-half the sum of the values, keeping in mind that values have opposite signs.

Ply steer and conicity forces receive a disproportionate share of industry attention from vehicle ride specialists. This is because both components occur in straight-ahead, free rolling motion on a level highway and cause steering wheel pull, mostly due to conicity, which is annoying to the driver. The magnitude of the resulting perturbation varies not only with wheel load and inflation pressure, but also with the direction of rotation of the tire. The resulting force may point toward or away from the vehicle centerline. Ply steer changes direction with clockwise or counter-clockwise motion, while conicity does not.

Lateral run out of a tyre.

Lateral run out (LRO) describes the deviation of the tire’s sidewall from a perfect plane. LRO can be expressed as the peak-to-peak value as well as harmonic values. LRO imparts an excitation into the vehicle in a manner similar to lateral force variation. LRO is most often measured in the upper sidewall, near the tread shoulder.

Tangential force variation.

Tangential force variation.

Insofar as the tangential force is the one acting in the direction of travel, tangential force variation describes the change in this force as the tire rotates under load. As the tire rotates and spring elements with different spring constants enter and exit the contact area, the tangential force will change. As the tire rotates it exerts a high traction force to accelerate the vehicle and maintain its speed under constant velocity. Under steady-state conditions it would be typical for the force to vary up and down from this value. This variation would be characterized as TFV. In a constant velocity test condition, TFV would be manifested as a small speed fluctuation occurring every rotation due to the change in rolling radius of the tire.

Dynamic properties influence tire construction: sidewall bulge and depression in a tyre.

Given that the tire is an assembly of multiple components that are cured in a mold, there are many process variations that cause cured tires to be classified as rejects. Bulges and depressions in the sidewall are such defects. A bulge is a weak spot in the sidewall that expands when the tire is inflated. A depression is a strong spot that does not expand in equal measure as the surrounding area. Both are deemed visual defects. Tires are measured in production to identify those with excessive visual defects. Bulges may also indicate defective construction conditions such as missing cords, which pose a safety hazard. As a result, tire makers impose stringent inspection standards to identify tires with bulges. Sidewall Bulge and Depression is also referred to as bulge and dent, and bumpy sidewall.