TIRE CONSTRUCTION TYPES: CROSS PLY OR RADIAL?

How it’s made: the tire construction.

As we know, the tire is not subjected by a compression load but by a traction load. In fact, a tire is considered a pre-tensioned structure in which the pressure inside is much greater than the outside one (almost 2/3 times).

From the construction point of view, the tire is a flexible toroidal structure filled with compressed air.

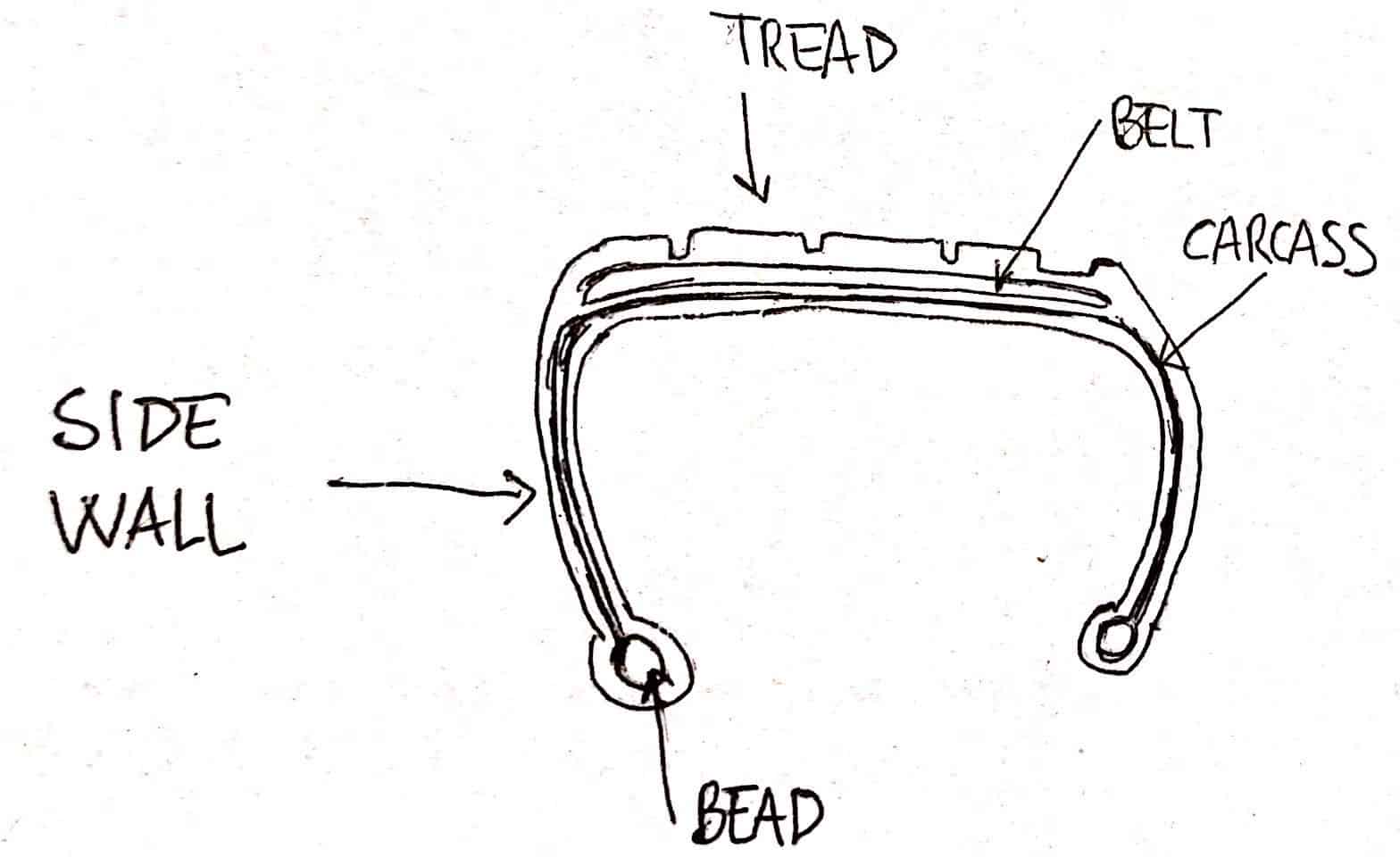

The structure of a tire consists essentially of five parts.

- bead;

- carcass;

- side wall;

- belt;

- tread

The benefits of cross ply construction and radial construction.

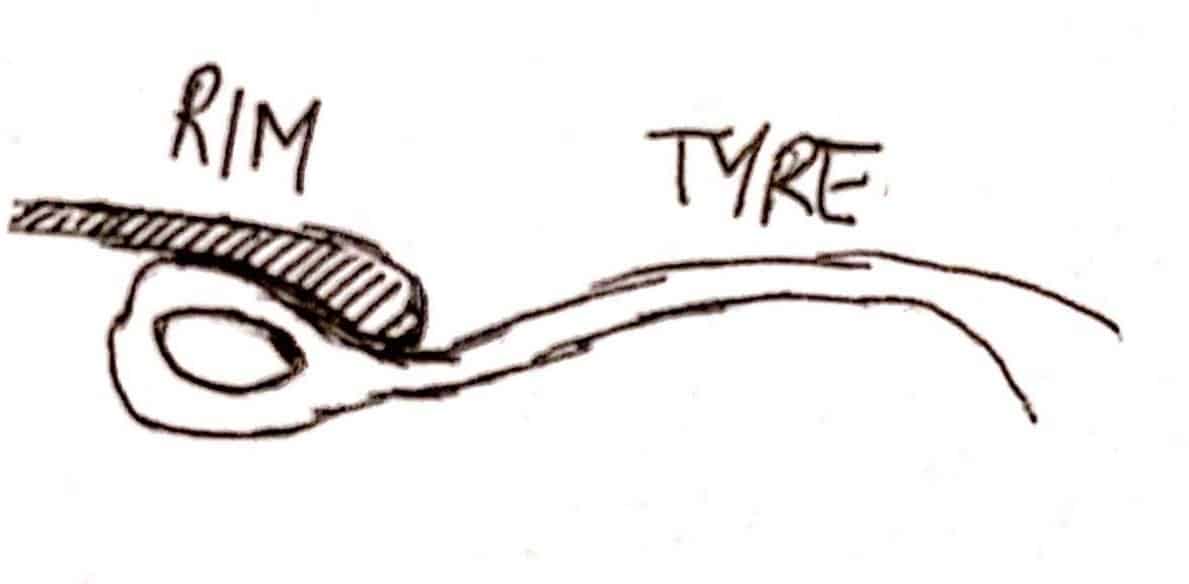

The bead ensures the fit on the rim and the air pressure seal. It is crushed on the edge of the rim by the internal pressure of the tyre (fig. 2) and, thanks to the friction, develops the forces necessary not to slip the tyre on the rim resisting the stresses coming from the ground (traction, braking, lateral forces in curve).

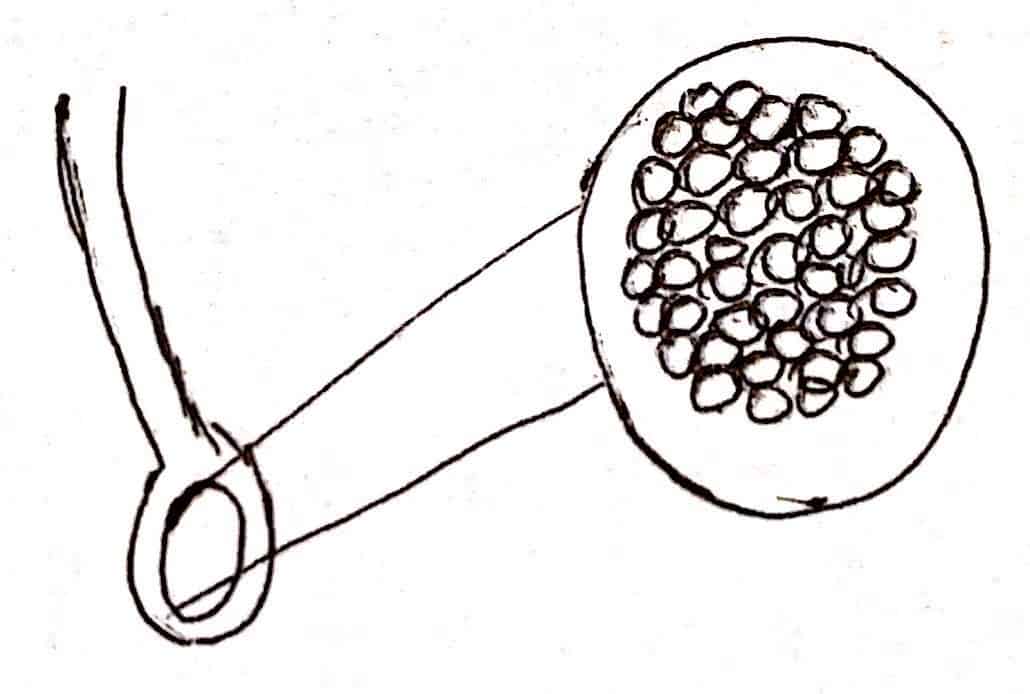

Inside it incorporates a metal structure (made up of a series of drawn steel cables with small section cables to greater flexibility) around which the carcass is wrapped (fig. 3).

The carcass wraps around the headband (fig. 3) and is made up of a number of layers of rayon, nylon or steel threads embedded in a rubber compound. To protect the carcass externally there is the sidewall, made of rubber, which must have excellent resistance to fatigue. In tubeless tyres, the internal part of the carcass is covered by a waterproof layer called inner-liner.

The tread, on the other hand, is the part of the tyre in which all the forces are exchanged with the ground and is therefore the area whose compound and geometry contribute substantially to the performance content of the tyre. Treads are very different from each other because are the main characteristic of the kind of the tyre: off-road, race, road, wet/dry, winter/summer…

Below the tread we find the belt, a band made up of various layers of steel wires that surround the carcass.

Radial tire and Cross-Ply tire Types.

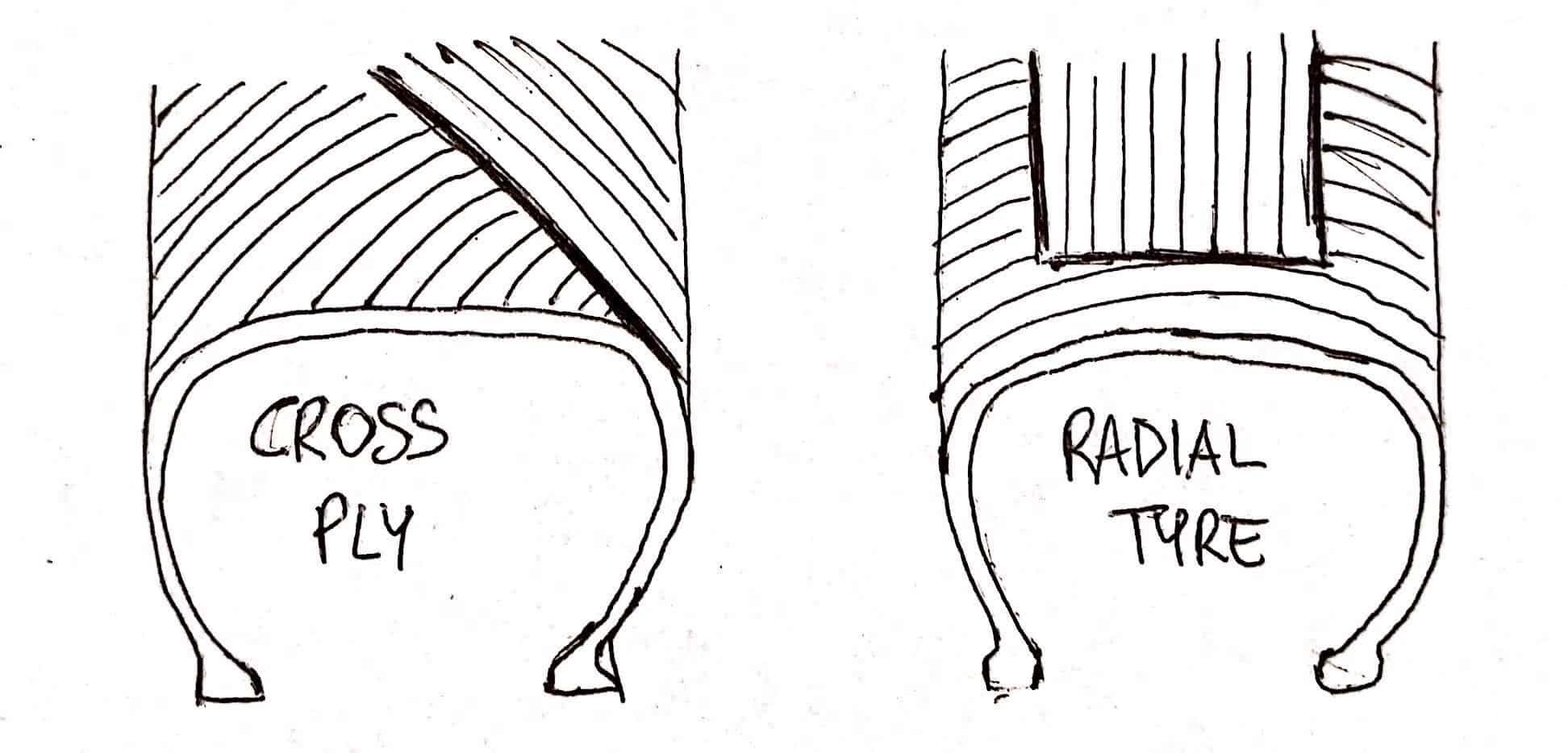

There are two type of tire constructions according to their structure: diagonal (or cross ply) and radial ply construction tyres.

The advatages of cross ply tire construction.

The first ones are made of various superimposed layers of carcass plies with threads arranged diagonally with respect to the equatorial plane of the tyre. The angle of inclination of the wires with respect to this plane is usually at 55°. Multiple rubber plies overlap each other and they form a thick layer, resulting in less flexibility which can make it more sensitive to overheating. Therefore, all high-speed tyres are with radial structure.

The advatages of radial tire construction.

The radial tyres (have you already seen the best in class Carlisle Radial Trail HD Trailer Tire-ST235/80R16 124L 10-ply?), on the other hand, have a belt and are characterized by a thinner carcass, as usually consisting of a single layer of metal wires arranged perpendicularly to the equatorial plane of the tyre (fig. 5).

The sidewall of radial tyres and the tyre tread work as two independent features. The flexibility of a radial tyre, together with its strength, are two combined factors which mean a radial tractor tyre absorbs impact shock and bumps more effectively than a cross-ply tyre.

The flexibility of the sidewall enhances vehicle stability and provides maximum contact of the tyre with the road surface. This, in turn, leads to a more comfortable ride and allows the driver to work longer. These tyres are also stronger, which means machines that use tyres like truck tyres or tractor tyres can be operated at higher load capacities.

Disadvantages of radial tyres include:

- The soft sidewalls are vulnerable when, for example, vehicles collide with curbstones.

Choose between cross ply construction and radial tire construction.

The crown of a cross ply tyre and the sidewall of the tyres are dependent on each other. The tyre does not come into as much contact with the ground as a radial tyre and this may lead to less engine power transmission or more site damage. As it does not absorb as much impact shock, the driver can feel more vibration. The initial cost of cross ply tractor tyres is cheaper than radial tractor tyres so they are often an attractive choice to anyone on a budget. The rigid ride a cross ply tyre provides can also be a benefit in applications where any tyre bounce would be a problem, such as on telehandlers or forklift machinery, so the rigid sidewall can be an advantage in certain working environments. That’s the end of our articles related to tyres composite structure, go on with part 3!